There are 250 known luminescent materials — things that glow by themselves. The most ancient of these is the ‘Bologna stone’ — made of the chemical Baryte — which was discovered in 1603.

Maybe one day, glow-in-the-dark materials could play a bigger role in urban landscapes replacing current light-emitting devices with pavements or other systems that glow by themselves what could significantly reduce global energy consumption and help cool the earth.

These materials absorb energy from sunlight during the day and release them as photons of light during the night. This prevents this energy from turning into heat.

In recent decades, research on persistent luminescence has led to new phosphors and rare earths with promising performances. Efforts to improve the quality of phosphors’ afterglow have paved the way toward innovative solutions for many disciplines. Several engineering solutions have been trying to get the benefits of luminescence in lighting energy savings and passive cooling of urban surfaces. Successful application of luminescent materials in the built environment is still on their early stages.

We at CONICA are continuosly monitoring and testing innovations on materials and processes to ensure the quality and reliability of our products, and as an example of an application using luminescence I explained the test in process of glowing granules I was doing at my posts of end of August, that was the second post on this issue after first one when my test satarted in June. On the August post I reported the results after the summer regime of light/darkness.

I’ve now completed my planned test adding the fall and winter regime with less light hours.

In the period from September to the end of February the regime has been about 9/10 hours of sunlight of different intensity during the day and darkness of 14-15 hours.

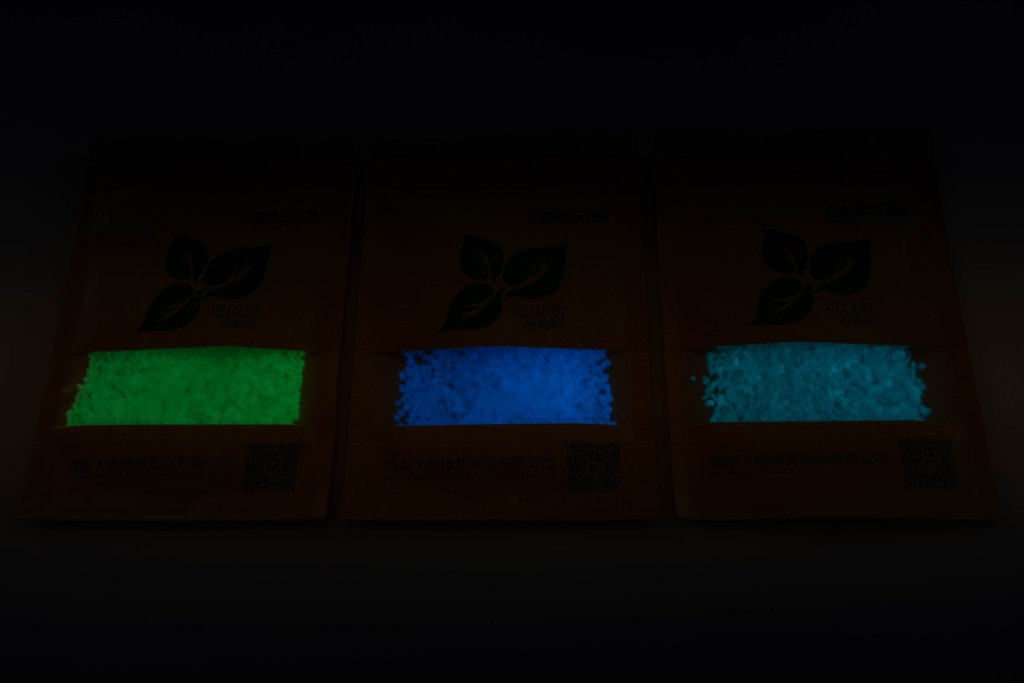

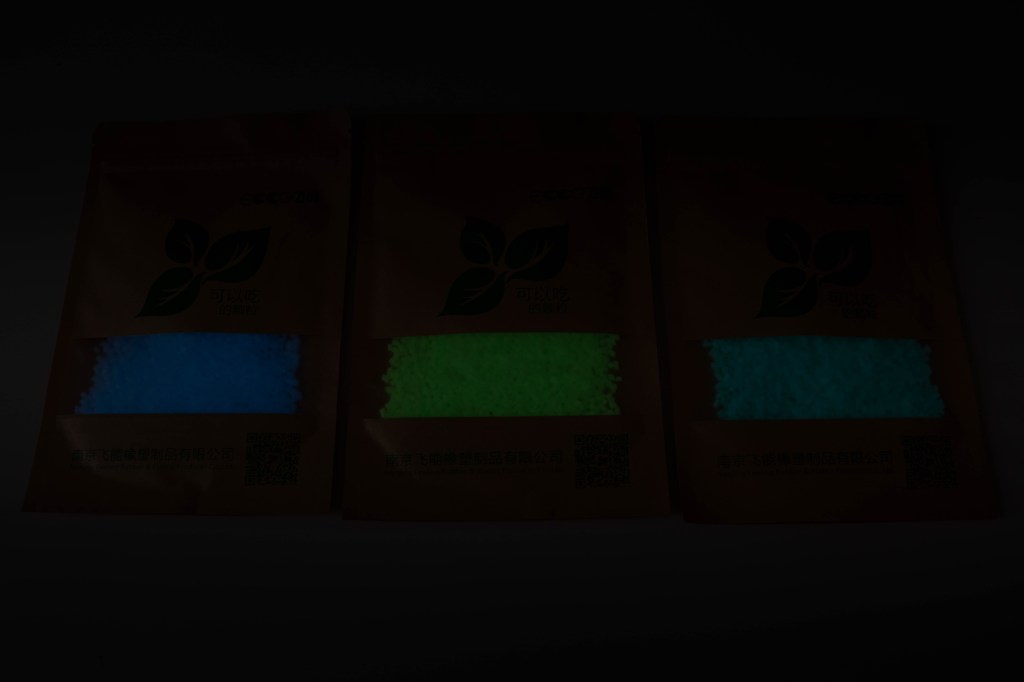

Granule samples of 3 different colour have been kept under this light regime: BLUE, GREEN and TEAL.

I kept the granules under their original film of transparent polycarbonate to avoid dust effects that would potentially reduce luminosity of the granules and the duration of the glowing effect. I cleaned the protective film at least once per week.

Observation of the samples have been done near every day one time during the night approximately 6 hours after full darkness.

In this new period of 6 months I did not notice any fading or reduction on luminosity on the glowing effect for any of the three colours. I’ve completed a total of 9 month of test.

After 5 hours in the dark is difficult to appreciate the colour difference between the three colour samples that were easy to tell apart on the first hour after darkness period. On my observations after 5 hours, you can not fully identify the initial colours. They really look very similar.

The photos below show the samples in daylight, with some daylight, in full darkness after 35 minutes, and after 3 hours of darkness.

These photos in the dark were taken under the following camera conditions:

ISO 125

Shutter speed: 10sg

Aperture: f / 10

Camera: Canon R5

Lens: Canon RF 24-70 f / 2/8 L USM

Lens Aperture: 70 m / mm

The aperture of f / 10 is aiming to have a high depth of field to achieve the material is focused in its entirety. The other conditions are aiming to preserve as much as possible the fidelity of the colours.

Test has been done during a total period of 9 month and although no measurements of luminosity were done, the subective impression is that there are no significant reductions on the glowing effect in this period.

Take care

References:

- Vineeth Venugopal (Medium) – New luminescent materials could replace street lights

- https://www.annualreviews.org/doi/10.1146/annurev-matsci-091520-011838 – Long Persistent Luminescence: A Road Map Toward Promising Future Developments in Energy and Environmental Science

- Nanjing Feeling Rubber & Plastic Products Co. Ltd.