About ten years ago, while visiting the FSB fair in Köln I was impressed by the vivid colours and the nice, rounded pebble looking on the flooring I saw on a booth from Polysoft that was one of the exhibitors in the fair near our booth.

Different Color mixes of Polysoft Play/Splash System

At that time, I was working as recently appointed Product Manager of a new line that KOMPAN A/S was launching for Safety Surfacing named Flexotop and I was interested in knowing all competitive products Worldwide on the Safety Surfacing segment, especially those for Outdoor Playgrounds , Fitness Areas and MUGA spaces.

For a few years we launched a great FLEXOTOP flooring system based on an EPDM wearing course and I was focused on developing projects, markets and product plans around this system. My friends at KOMPAN improved the system once I moved to a new professional challenge and I continued working around sports and playground poured in place rubber flooring at CONICA AG also using mainly EPDM rubber granules.

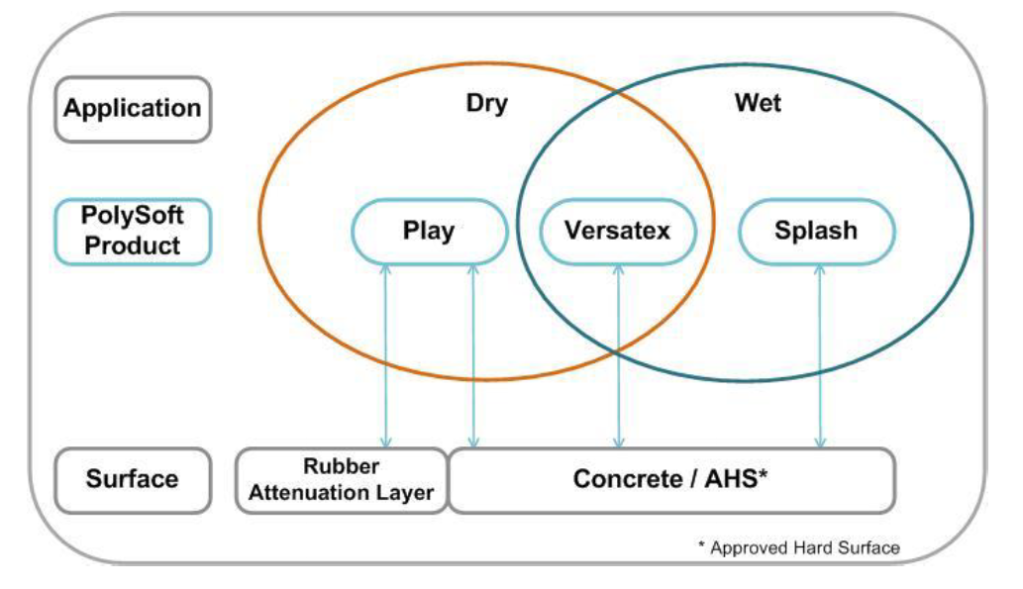

Now, as a freelance, I have the opportunity of testing and learning about other solutions as the Polyolefin based systems supplied by Polysoft and I will explain today one of their systems with some others following on next posts. As always, each system has its benefits and drawbacks, but I see this SPLASH system particularly well suited for all kind of wet areas although there is a similar PLAY system also offered for dry ones.

An overview of some of the Polysoft systems

The PolySoft is a seamless site-applied, poured-in-place, surfacing system suitable for a broad range of applications. Made from polyolefin pebbles or beads using sophisticated manufacturing techniques they have pigments with one of the highest grades of UV resistance I’ve seen. The PolySoft Play/Splash system pebbles (polyolefin plastomer particles) are chemically bonded with PolySoft two-part moisture cured aliphatic and uses water-based epoxy or aromatic urethane primers for surfacing preparation.

Waha Splash Club in Bahrain

The system may be installed on top of a rubber base attenuation layer of SBR at the appropriate thickness to achieve desired fall height requirements as specified by the playground equipment manufacturer. The base material would be mixed with an aromatic binder to achieve necessary compaction. The ratio of binder to rubber depends on your locally available SBR granule size distribution but usually is around average 15% by weight, although I’ve seen a ratio range moving from 9% to 16% at different installers. On wet applications there is generally no rubber attenuation layer as usually there is no need of fall height attenuation on waterpark play equipment.

Waha Splash Club in Bahrain

For top wear layer, the Polysoft pebbles are supplied in 14Kg bags of two different sizes, The large Pebbles have a diameter about 2 to 2,5mm and the small ones about 1 to 1,5mm.

You would mix 3 bags of Large and 1 bag of Small Pebbles with 5,3Kg Aliphatic Binder Part A and 0.4Kg Aliphatic Binder Part B for High Impact Splash applications. There is also a Polysoft Splash Plus system formulated with some additive for anti-Microbial Protection.

As the material is not rubber but a thermoplastic, it’s not vulcanized so it could be recycled forever.

The most suitable applications are Water Playgrounds – Water Parks – Waterslide Entrances – Splash-Pads – Hydrotherapy Pool Concourses – Pool Decks – Pool Surrounds – Spray Park – Wet Area Pathways – Lazy River – Beach Zero Depth Entry to Pools and more.

There are up to 18 colour options and hundreds of colour mix combinations but certain colours perform better in an aquatic environment than others. PolySoft recommends using for ‘Splash’ an identical colour of small pebble to one of the colours selected in the larger pebble.

Waha Splash Club in Bahrain

The system is fungal and chlorine resistant, has excellent skid resistance and amazing colour UV stability, is easy to clean, non-toxic and has a very good strength, but my preferred advantage is that is cooler on barefoot that any other surfacing and although the pebbles are harder than rubber granules the rounded shape make the feeling and walking on barefoot great.

A PolySoft ‘Splash’ PLUS system adds additives for hindering algaecide and microbial growth on the surface. The antimicrobial protection cannot leach from the PolySoft surface, nor be wiped or washed away and has been successfully tested against over common bacterial organisms showing a significant reduction of bacteria growth without development of resistance over time.

The pictures in this post show a project in Bahrain. The climate there begs opportunities for kids to play with water and at the same time creates severe challenges to the surfacing due to the high temperatures and UV radiation level. Premier Q a long-time partner of PolySoft in developing splash pads in Bahrain and Saudi Arabia, made this water project at the Amwaj Islands residential area. The Waha Splashclub it’s worth a visit.

I will talk about other systems on the next couple of posts.

You can get additional information about Polysoft products or get product samples at:

Take care