One of the visual defects you may find on an EPDM rubber surfacing job is the whitening on top of the initial colour after some time, usually a few months. There are some colours that seem to be more conducive to presenting the problem, and normally you can find this anomaly on lower quality EPDM. Luckily the products we sale at CONICA are among the best quality manufacturers and we do not face this claim when we supply the EPDM.

Some of my readers may be working on the EPDM manufacturing business, so I will be more than happy to receive your more expert opinion and comments. I will try to explain in easy terms what I have learned about this problem and for that we need to also review how the EPDM granules are manufactured. Don’t expect a scientific paper here, you know that I always prefer to find easy explanations.

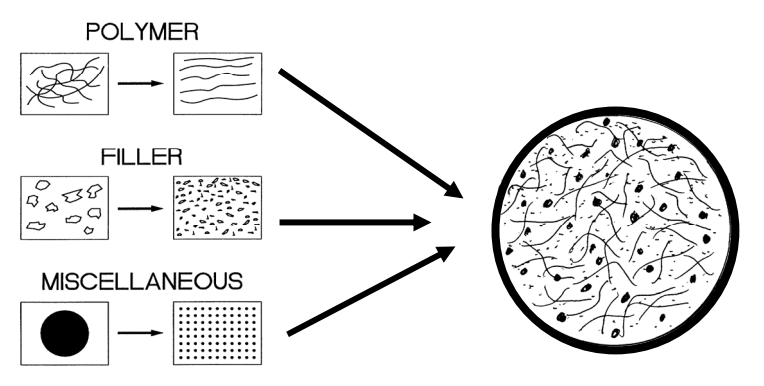

The EPDM granules we use in our flooring installations are EPDM compounds made up of 4 main ingredients: EPDM virgin Polymer, fillers, plasticizers, crosslinkers , pigments and auxiliary miscellaneous materials. The mixing is normally made in a continuous process using Banbury pressure and temperature mixers or other variants of kneading machines.

The formulation may contain between 20 and 30 inorganic or organic components.

Additives serve a variety of purposes as for example reinforce using carbon black, antioxidants, and UV stabilizers to protect the polymer against atmospheric conditions, flame retardants, accelerators for the vulcanization curing process as sulphur or peroxide and others with different targets.

Among the main fillers used are talc, calcium carbonate and “Kaolin” clay. These fillers are in powder and are added to cheapen the mix (usually these fillers do not enhance the properties).

At the completion of the mixing process, the final compound is dropped onto a sheeting mill to form slabs or sheets of compound, cooled and stored prior to the calandering or rotor die extrusion process, where it is converted into a laminated membrane still uncured, meaning that it can be moulded or formed using heat into other shapes and is very tacky to the touch.

Because the EPDM is very tacky and has yet to be cured, it would stick to itself if rolled up without some type of anti-blocking agent. So, a « dusting agent » is applied immediately after the panels are spliced and just before they are rolled up for curing. Typical dusting agents are Talc or Mica.

The uncured EPDM is placed into the autoclave for a pre-determined length of time to cure under heat and pressure. This is the vulcanization curing process that changes the material to a rubber state, making it extremely durable and resilient to heat, ultraviolet exposure, ozone as well as extreme cold and hot temperatures. Finally, the membranes are granulated and bagged, and this is the product you use in the flooring.

When you see a site that is whitening you already intuit that it is all about the filler that is usually white or pearl colour but how is this happening?

We have discussed this internally at our team and there are two potential explanations:

One of them is, according to a 2012 scientific study we found recently, the whitening is independent of the type of filler used and is due to the formation of calcium stearate as a result of the reaction between the calcium of the filler in humid atmosphere or the calcium present in the tap water from irrigation or cleaning and the stearic acid. The stearic acid is coming from some of the plasticizers used on the EPDM mixture.

The other potential explanation is that filler is released after some exposure to UV radiation, creating this “whitish” surface.

Whatever is the reason, as the chemical composition and properties of the pigments are different among them, there are colours that may be more prone to this whitening than others. The UV stabilizers used in the formulation are destroyed during exposure to this radiation and this happens more quickly with bright colours (orange, yellow) than with others. Using an aliphatic top coat would help to delay this progress.

I think a good and tested formulation with selected good quality raw materials combined with a well-controlled and monitored process for EPDM mixing and vulcanization will ensure a more permanent mix of all components and avoid this migration of the filler that will show white areas in your flooring, whatever the end reason is for that to happen.

As usual the cheapest product at purchase time may end being the most expensive at the end.

Take care

Sources:

- Robert Dickstein – Technical Rubber Course – June 2003

- EPDM Membrane Production: Materials and manufacturing process

- Journal of Applied Polymer Science – Volum 123, Issue 4 – Sung-Ho-Ha, Hye Seung Chung, Yong Tae Joo and Kyung Mo Yang – South Korea – February 2012

- Granulogy: Success based on knowledge of rubber – Gezolan AG.