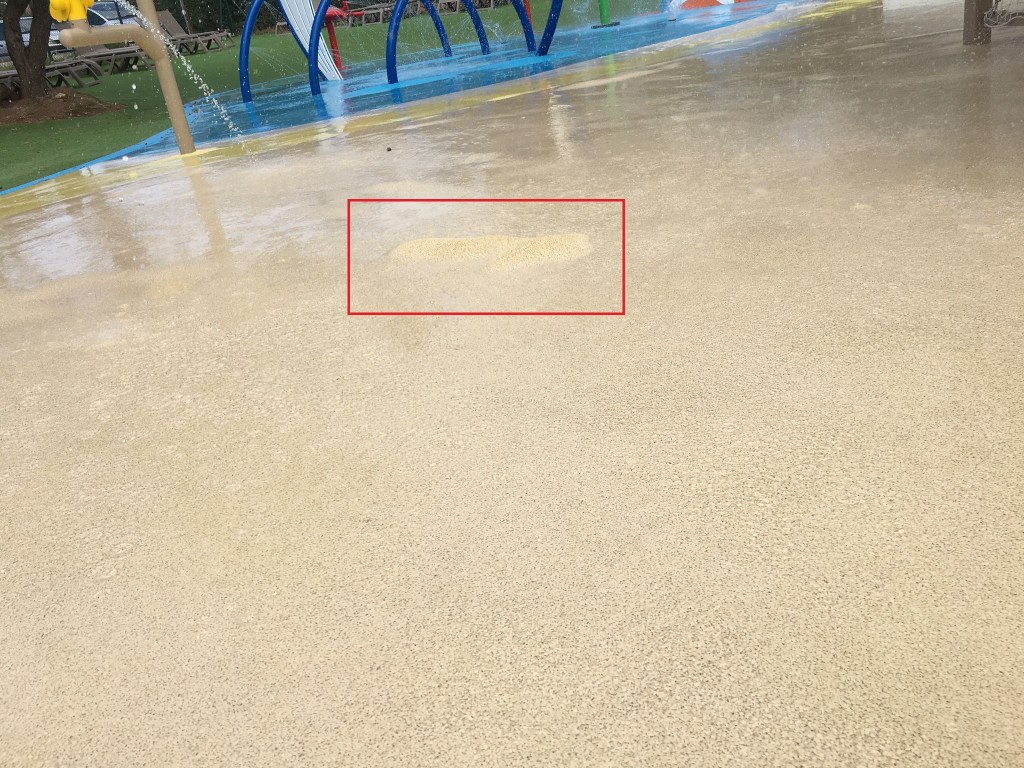

This is not a common problem on rubber surfacing jobs, I’ve seen it just a couple of times during the last 12 years. I will talk in this post about the appearance of wrinkles or bubbles in the top EPDM layer.

In both cases the problem showed up in a site using a single layer 15 or 20 mm rubber surfacing installed over a concrete sub-base.

There are several causes for this problem that I have been able to confirm by inspection on the site. I’ve also asked about other potential causes to my team of expert technicians at CONICA. These are the potential causes that we envisage:

- Drainage problems on the sub-base that cause accumulation of water between the rubber layer and the concrete slab that hinder the adhesion between both, displacing the rubber layer in a wrinkle as if it were a free carpet or generating a bubble on a pond area with accumulated water.

- Lack of priming of the concrete sub-base that preclude good bonding of the flooring to the sub-base in connection with the expansion and shrinking of the rubber flooring according to the ambient temperature.

- The rubber surface is “locked in” by concrete or other edge constructions, so that the surface can not extend to the sides, which may lead to bubbles if bonding to concrete is insufficient.

Of course, if a single layer of rubber is installed on a concrete sub-base without previously priming the concrete or ensuring it is dry enough, we are probably giving the possibility that in case of expansion under warm temperatures, the rubber mat can only move upwards creating a bubble.

Assuming that sub-base drainage is correct, priming of the concrete either using an specifically designed primer or the same binder used in the flooring a little bit diluted and rolled on the sub-base is essential to ensure the bonding of the rubber layer and avoid to be in a bubble or to show wrinkles.

Take care