I’m back from my summer holiday and as I promised in my latest post, this time I will write about Emission Level of volatiles in our indoor projects using wepour rubber.

For wetpour rubber flooring on indoor projects the flammability explained on my previous post and the emission level of volatile organic compounds are the two most relevant features to add to the normal performance requirements of outdoor projects. You also need for indoor projects an impermeable system solution to make it easy to clean and reduce the risk of pollution.

To achieve these requirements the CONICA indoor playground system uses several coats of a pore sealer and a top sealer coat.

Volatile Organic Compounds

Volatile organic compounds (VOCs) are emitted as gases from certain solids or liquids and are an important cause of indoor air pollution. VOCs include a variety of chemicals, some of which may have short- and long-term adverse health effects. Concentrations of many VOCs are consistently higher indoors (up to ten times higher) than outdoors. VOCs are emitted by a wide array of products.

Organic chemicals are widely used as ingredients in household products. Paints, varnishes and wax all contain organic solvents, as do many cleaning, disinfecting, cosmetic, degreasing and hobby products. All of these products and the ones we use in rubber flooring can release organic compounds while you are installing them, and, to some degree, once installed.

The method for the determination of volatile organic compounds is based on the standards DIN EN ISO 16000-9, DIN EN ISO 16000-11 and DIN EN ISO 16000-6.

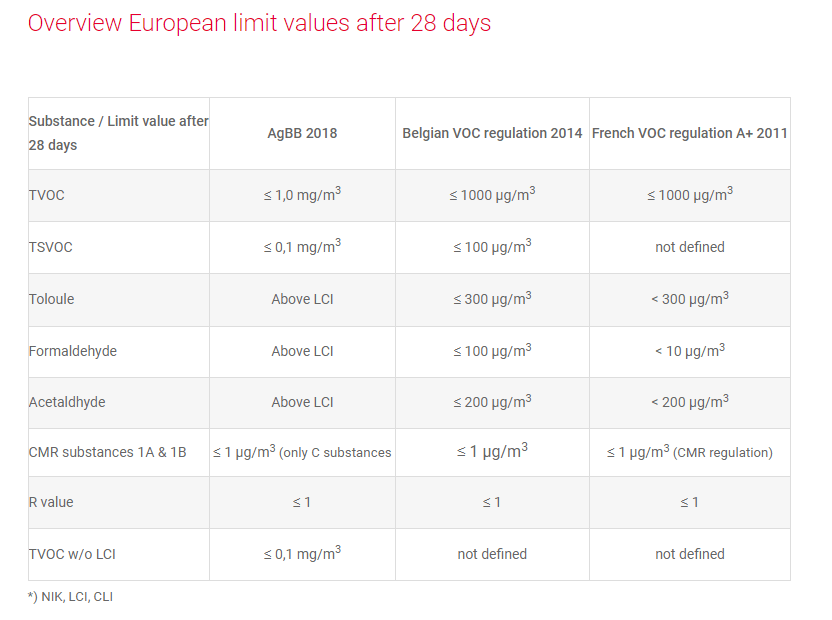

For the test of a flooring, the system sample is placed on the center of a test chamber at controlled temperature, hummidity and air exchange rate and the gas samples are analyzed by means of gas chromatography /mass spectrometry. Values are measured after 3 days and after 28 days and limits are compared with one of the existing schemes for building or construction materials. CONICA uses the AgBB scheme on its certificates for indoor system.

AgBB scheme

The AgBB scheme is probably the most important European test scheme for product emissions and defines with its requirements the suitability of the tested products for indoor use (hazard prevention). The German Committee for Health related evaluation of Building Products was founded in 1997 and developed a test criteria for VOC emissions from construction products known as AgBB scheme that is regularly reviewed and edited, the last time in August 2018.

The parameters measured forms the basis for many voluntary test labels, such as the Blue Angel, GEV emicode or th eco-INSTITUT-Label, which represent a recommendation for low-emission indoor products also for more sensitive persons.

Products that meet the AgBB requirements are also recognised for use in international LEED building projects. AgBB tests can additionally be evaluated according to legal requirements (e.g. in France and/or Belgium) or for applying for voluntary test marks.

Health Effects of excess emission

Health effects of excess emission or lenght of time exposed to highly toxic volatiles may include:

- Eye, nose and throat irritation

- Headaches, loss of coordination and nausea

- Damage to liver, kidney and central nervous system

- Some organics can cause cancer in animals, some are suspected or known to cause cancer in humans.

Key signs or symptoms associated with exposure to VOCs include:

- conjunctival irritation

- nose and throat discomfort

- headache

- allergic skin reaction

- dyspnea

- nausea

- dizziness

Take care