Many building materials are noncombustible. Examples of noncombustible building materials include brick masonry, concrete blocks, cement, metal and sheet glass. Our wetpour rubber flooring solutions as other common materials used in construction as, for example, wood are considered flammable and when used on indoor building projects they need to be compliant with construction rules and standards regarding safety and quality.

Flammability is the ease with which a material is ignited, the intensity with which it burns and releases heat when ignited, the propensity to spread fire, and the rate at which it generates smoke and toxic combustion products during burning. It is then associated with fire hazard and depends on many parameters related to the material and its end use and environmental conditions. Ranking or classifying the materials from measurable parameters on a common lab test procedure is the easier approach to evaluate this risk.

The flooring has a specific set of structural, durability and safety requirements. There are requirements for synthetic indoor flooring, such as the emission level of volatile organic components, which could affect the health or comfort of inhabitants of a building, which we may discuss in a future article, but today I will focus on flammability classification of the materials, we commonly use on wetpour surfacing and the possible combustion smokes generated in the event of a fire.

Standards such as the British BS-7188: 1998 + A2: 2009, one of the most complete in terms of requirements and test methods for Impact absorbing playground surfacing, includes a method (Method 7) that checks the ease of ignition of synthetic flooring.

For indoor buildings, the most relevant standard in Europe and other parts in the world is the EN 13501-1 + A1: 2013. This standard allows to classify the materials used for construction and building based on their behavior against fire and establishes the tests to determine the reaction to fire, such as the EN 13823: 2010 or EN-11925-2.

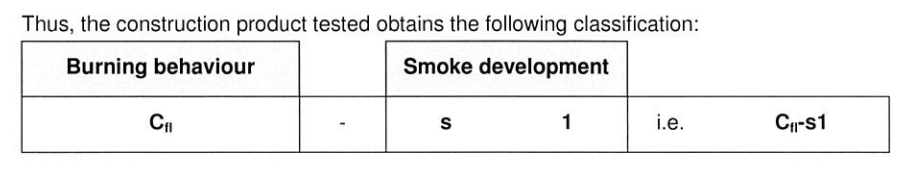

Most methods measure not only the speed of fire spread and the emission of ignited particles but also the emission of smoke.

For a flooring with an SBR cushion layer and a standard EPDM top wearing layer, the classification that can be obtained is usually class Efl, but even class Dfl can be obtained for small SBR thicknesses. In the absence of an SBR layer, the classification obtainable with a standard top layer only of EPDM granule is usually Dfl.

Using granules with flame retardant additives, available at some manufacturers it is feasible to achieve Cfl. Floorings with Bfl ratings may need a different non-granulated solution and could as well depend on the thicknesses.

In relation to the production of smoke, the classification obtained in almost all the cases that I know of is -s1 although obviously it can also depend on the formulation or composition of the materials.

Speaking about fire, it’s summer time with really hot temperatures in my region, so I have two good news, one for me and one for you all:

- I will take a few weeks of summer Holiday this July

- You can rest from reading new articles on my blog until the end of July

Take care and enjoy if you are also having Holiday.