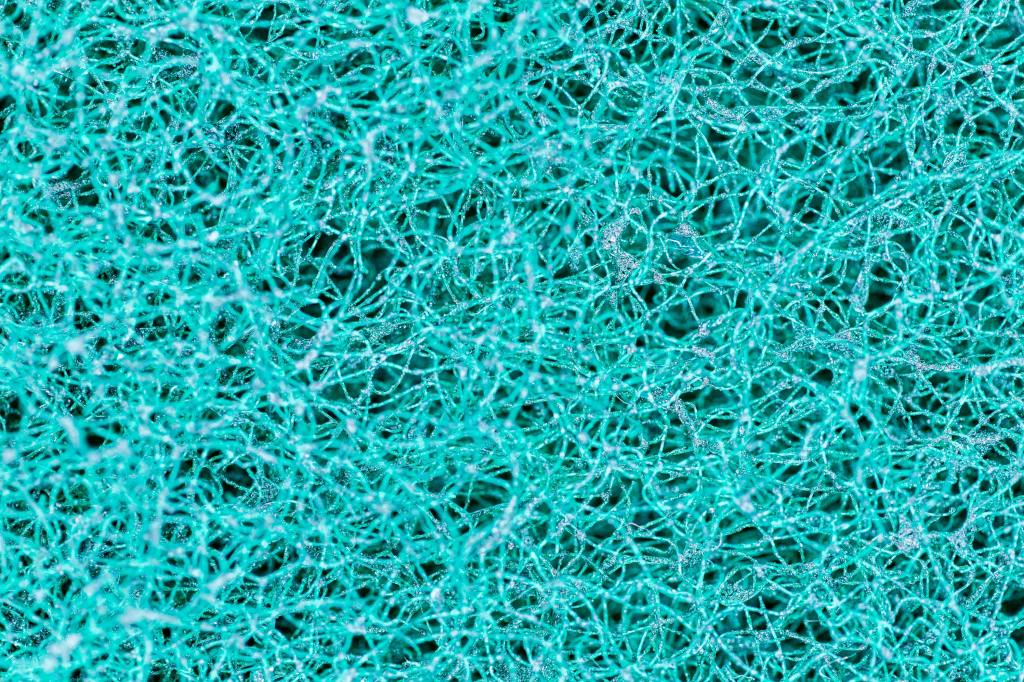

Vulcanization is a process that converts the plastic characteristic of an EPDM compound from deforming under a certain force to becoming an elastic thermoplastic that returns to its initial position after deformation by said force. Thus, vulcanization creates a permanently elastic and thermally stable product that we call a rubber or elastomer. Through this vulcanization process, the hardness, tensile strength and resistance to wear of the original product are increased and the elongation at break and tensile strength are optimized. The process takes place at pressure and temperature of at least 150ºC for a controlled time.

During vulcanization, disordered molecular chains create lattice-like crosslinks that can return to their original position after application of a force. The mechanism to achieve this is to add to the mixture a chemical substance that acts as an agent that facilitates or accelerates these cross links. The substances commonly used for this are Sulphur or Peroxide. These substances manage to form a three-dimensional network of bonds by reacting with the molecules of the rest of components of the EPDM mixture.

Sometimes installers ask me what EPDM is better, a sulphur or peroxide vulcanized one and I explain my answer in simple words as shown below.

Sulphur vulcanization is the most frequent because sulphur is a cheap substance, little toxic and is compatible with all the additives that are used for EPDM production. Vulcanizing with this agent has simpler temperature, pressure and time control parameters. Its main drawbacks are that the granule can have a more unpleasant odor and from the point of view of environmental requirements it is a less favorably viewed substance.

Peroxide vulcanization requires more complex handling and storage for the EPDM manufacturer due to the reactivity of some of its components and requires that the control of temperature, pressure and oxygen presence parameters during the vulcanization process be carefully controlled. Its use facilitates compliance with environmental requirements by the manufacturer, although its cost is somewhat higher than sulphur. The end result of peroxide vulcanized EPDM is a granule with very good flexibility and thermal aging, without odors, better UV stability and very suitable for all applications and especially those around swimming pools or water parks, specially those using marine water.

So my conclusion is that they both produce granules with very similar characteristics for flooring installers with only a small price advantage for sulphur and a bit better UV and chloride or salt water protection advantage for peroxide.

More important for optimizing the properties and performance of the granule and consequently of the final rubber flooring is the composition of the rest of the substances used to manufacture the EPDM granule such as fillers, softeners, UV stabilizers, oils, ethylene polymer and diene. and colorants.

As a summary, the main issue to consider is the quality system of the manufacturer including both the process and the raw components that are used regardless of which is the vulcanizing agent.

Take care