Binder is the component with the highest impact on the cost of a wetpour (poured-in-place) rubber flooring but also on the end quality achieved.

With the enormous price competition of our business segment, specially at some countries, I have seen installers trying to save costs in multiple ways and one of them has been, in some unfortunate cases, to reduce the proportions of binder recommended by the polyurethane manufacturers or the recipes specified by the full system suppliers.

A really bad idea. Give up this temptation immediately.

The proportion of binder used has different impact on the absorption layer and the top layer, but in both cases:

- It influences the tensile properties and therefore the mechanical stablity and durability of the layer (both layers).

- It influences the cushioning or impact absorption capacity of the layer (specially for cushion layer).

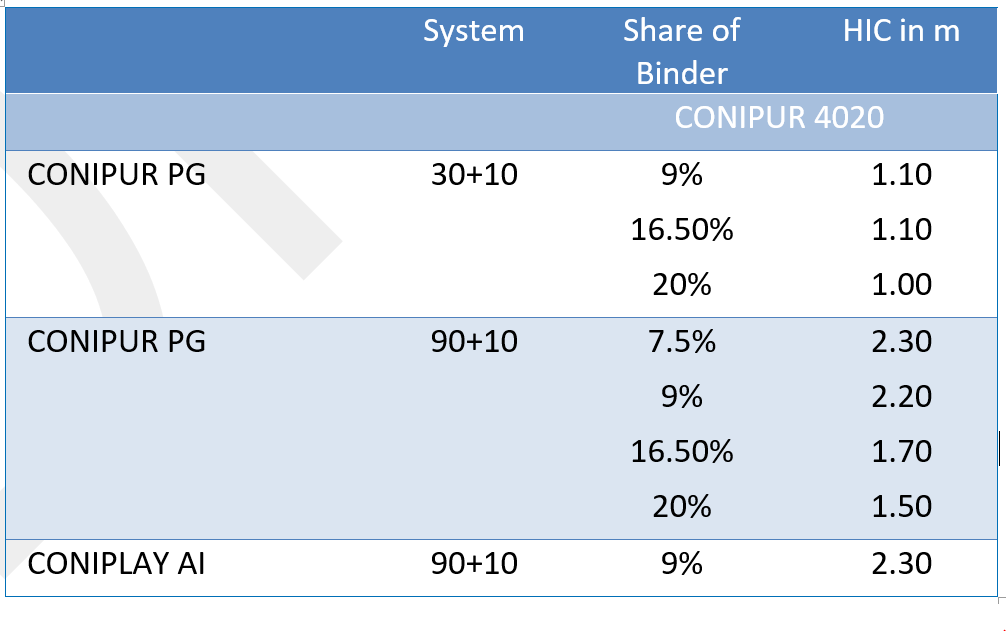

Let’s start with the absorption layer. A high proportion of binder in this layer increases tensile properties, but can greatly reduce the critical fall height (CFH), especially at higher thicknesses. A ratio below that recommended by the supplier can give better critical fall heights, but would disintegrate and be destroyed in a short time, causing problems of stability and generating puddles or cracks in the top layer.

The recommended percentage for base layer depend on the size and type of the granule, but a suitable average value for SBR granules of 2-6 mm would be between 8 and 9% of binder. For regular buffings you would need a bit more with 10-12% being quite common.

In the top wearing layer there is no significant influence on the impact absorption capacity, so reducing the percentage of binder has no positive influence on it and instead puts the durability of this wear layer at a serious risk.

The recommended percentages of binder for top layer are between 17,5% and 20% depending on the type of granule and system. Recycled granules require a higher proportion of binder to maintain sufficient tensile properties and durability and in this case around 22-24% is a common recommendation.

If you put the life span and guarantee of your work at risk in order to obtain cost savings, you can end up paying a very expensive price in the form of warranty, repair or brand image costs and I guarantee that I have seen this phenomenon on several occasions.

I have also seen some cases where the choice of a cheaper binder has skyrocketed repair and warranty costs or even bankrupted a company.

Binder is a key component for the quality of your work so don’t play dice with its proportions or quality.

Take care