One of the great advantages of wetpour rubber flooring is the possibility of making very creative designs with basic colours, blends of different colours, graphics or logos and 3D shapes that serve as play elements, thereby increasing the playful value of the safety flooring.

For years the only option rubber flooring installers had was to mix on site the different bags of basic EPDM colors in certain proportions and for graphics to explore their talent as draftsmen, marking the design in the SBR of the graphics imagined by the creator or build templates to be able to shape the graphic or 2D logo and later cut or make good wet to wet joints of the colours. A complex design, considering that colour changes require cleaning the mixer and may require, depending on the case, having to wait for the previous one to cure, could mean several days of work to complete an small area of graphical complexity.

Colour blends

Depending on the proportions of the mix, making them on site can be more challenging than it seems at first sight. Small differences in the proportions or in the bulk density of each of the colours can cause visible differences in the appearance of the flooring, once it has been already laid and impossible to see before laying. A proportion of two or three colours in equal proportions is relatively simple. By pouring a bag of each one of them into the mixer, the proportion can be accurate enough, but other proportions can be more complicated to perform unless you do careful weighing of each colour to blend.

To make things easier, most EPDM suppliers have standard blends already bagged on the common 25 Kg (55 lb) bag. These blends, made in the factory in big batches of several tons, can be made with precision dosages and large mixers that minimise the effect of bulk density differences between the colours to be mixed. Also, most have tools on their website to design and visualise different proportions of the blend from which the order can be directly made. A good example of these colour mix tools is the one recently introduced by the surfacing installers SpectraTurf. With these tools you can design the perfect blend for your project creating the custom look by combining the colour variants of rubber granules.

Some manufacturers as MELOS, which are showing in the last few years great innovation, introduced their Stylemaker® Colour Flow, offering on their website a configurator for colour gradient blends packed in the different proportions of the desired transition. You choose the colours of the gradient through their website and place the order, saving time, calculations and blending difficulties. The supplier sends them mixed in the appropriate proportions and quantities as well as installation sequence to get a nice gradient.

2D and 3D graphics

Over time, some suppliers of prefabricated EPDM graphics of suitable thicknesses for the top layers of 10 or 15 mm have appeared on the market, which greatly facilitate the work and improve the result without depending on the drawing and execution skills of the installer. The manufactured graphic is simply glued in place on the SBR and the EPDM is then installed and smoothed around it, ensuring a good primer of the edges of the graphic with the new EPDM to avoid any further separation risk.

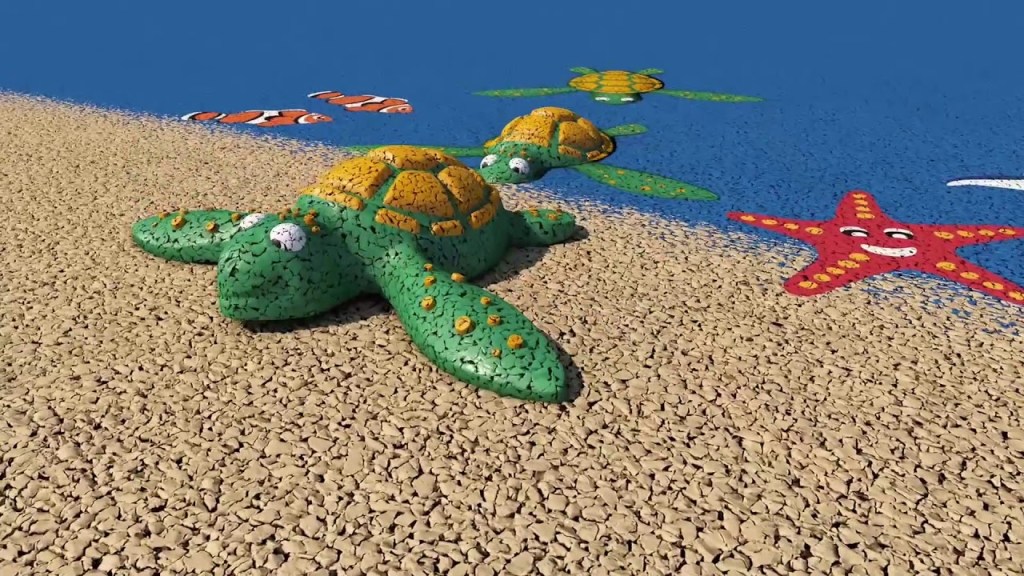

Later on, 3D shape solutions appeared such as the wide range of Playtop® animals of around 1 m in height or the smaller 3D prefabricated pieces and heights of up to 600 mm from companies such as 4Soft, that allow the flooring to become a additional element to play or integrate into a themed environment with the rest of the playground equipment.

The installation of these prefabricated 3D elements is equally simple and fast, in some cases using adhesives for gluing to the SBR and in the case of some big 3D elements of Playtop or the spheres through plates, bars or auxiliary mounting subsystems with adhesives.

The cost of the pre-made 2D or 3D elements fully compensates for the significant reduction in the installation time of the flooring that would be required to made them on site. The level of quality of pre-made ones will also be quite higher as the conditions on site cannot match those of a workshop or manufacturing plant.

Once again, MELOS® has shown its innovation value by introducing its Stylemaker® with an APP that facilitates the creative design of 2D and 3D images by selecting the motif, sizes and colours to order directly. You will receive an image or shape that can be installed over the SBR using a polyurethane or silicone glue.

Take care