The machine to create the appropriate state of the mix of rubber and polyurethane is one of the main investments a safety surfacing installer needs to do to ensure good quality jobs. It’s important in terms of final results you can achieve and efficiency but also is one of the most expensive tools you will need to buy. And first of all forget it, never, ever use a cement mixer.

I’ve seen a lot of different forced action mixers during my visits to job sites worldwide and near all of them were doing the job properly, but there are several characteristics that can make the difference and the installer live easier. This post will talk a bit about mixers and what I would recommend about them based on the experience I had in the past.

What do you need from the mixer?

There are several things that I think you need to consider as main requirements when selecting your forced action mixer:

- Easy to move on site and to transport to the site

- Capacity for at least 75 or more litres to use it on top and cushion layer mix

- Rotation speed of 25-30 rpm

- Easy to clean vessel and outlet as well as removable blades

- Top grid door to prevent big objects or lumps of granules to fall on the mixing vessel

- Electrical or diesel/petrol motor

- Long duration, stability, safety and reliability

My personal preferences:

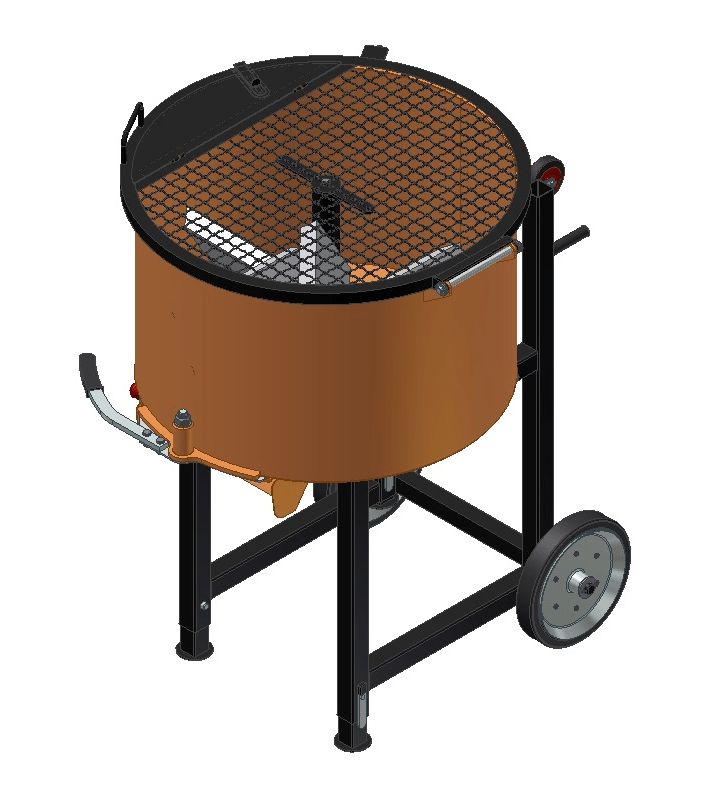

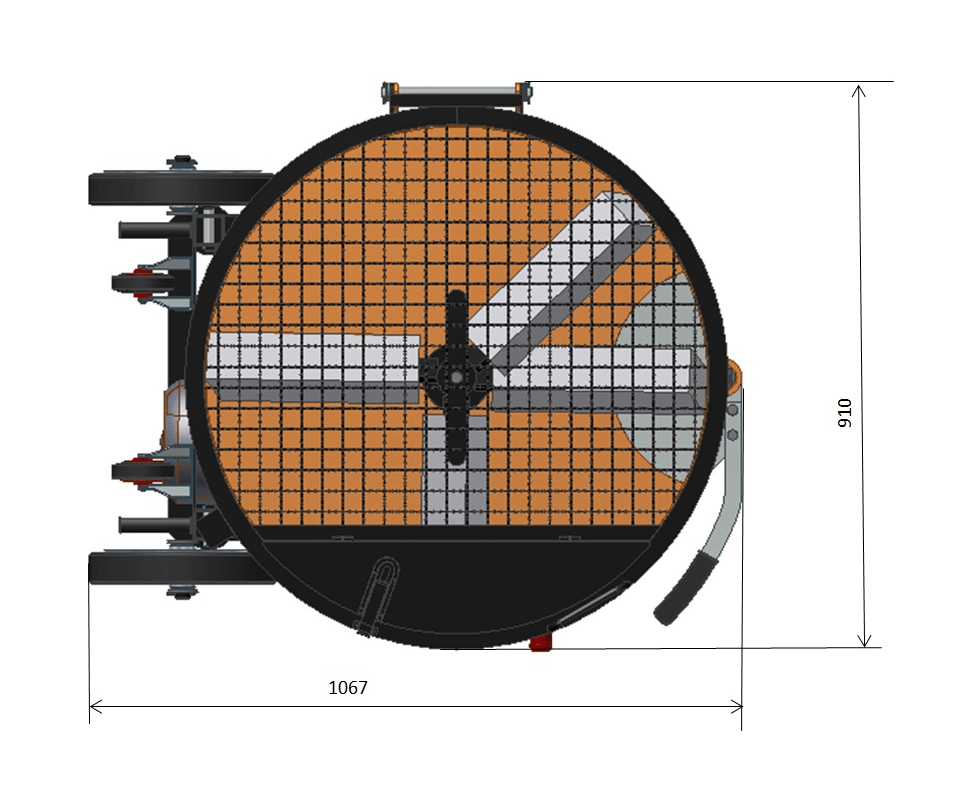

- A pan type with electrical motor, top opening and bottom outlet door handle to deliver the mix easily to your wheelbarrow

- Start-Stop and Emergency Stop buttons and a good earthing connection

- A cover for the motor to protect it from dust, soiling and hits

- Wheels for easily move it, load it on the van and transport it to the site (remember this will be around 150 kg to move)

- A capacity of minimum 3 bags of granules (75 kg)

- 3-4 plastic and removable blades to make easier the cleaning process and reach all sections of the vessel

- Adjustable feet height to adapt to the job site needs

- A well designed handle and outlet door for discharging the material

Easy to clean is a very important requirement for top layer mixes, as you will need to clean the machine for each colour change you do and you might have to do this several types in a day or at least one time at the end of each labour day.

I may admit you could prefer a petrol/diesel type in some cases but generally you have always electricity available on site by using some kind of electric generator for all other tools that can only be electric.

If you are doing very big areas or athletic tracks with a lot of cushion layer mixes you may need more capacity. There are types of 250 or more litres that may match better these cases.

Manufacturers/Suppliers of mixers:

- CRETE ANGLE

- ROTATUB

- BARON

- KOMPAN-FLEXOTOP

- YAYUNTAN

- HANGZHOU GREEN VALLEY RUBBER PRODUCTS

I will be happy to have your feedback with comments about this issue and the products you would recommend or not according to your experience.

Take care