Frequently, the clients ask us for the certificate of critical fall height and thickness of safety surfacing for playgrounds made on samples with our materials.

As I have repeated it many times to different clients, I have thought that I better explain here some relevant information about this issue. In the future to those who ask me, I will send them a link to this publication as I believe safety on the Playgrounds must be a top priority. I try to offer here the most complete information that I can provide, without making it too much technical or difficult to read.

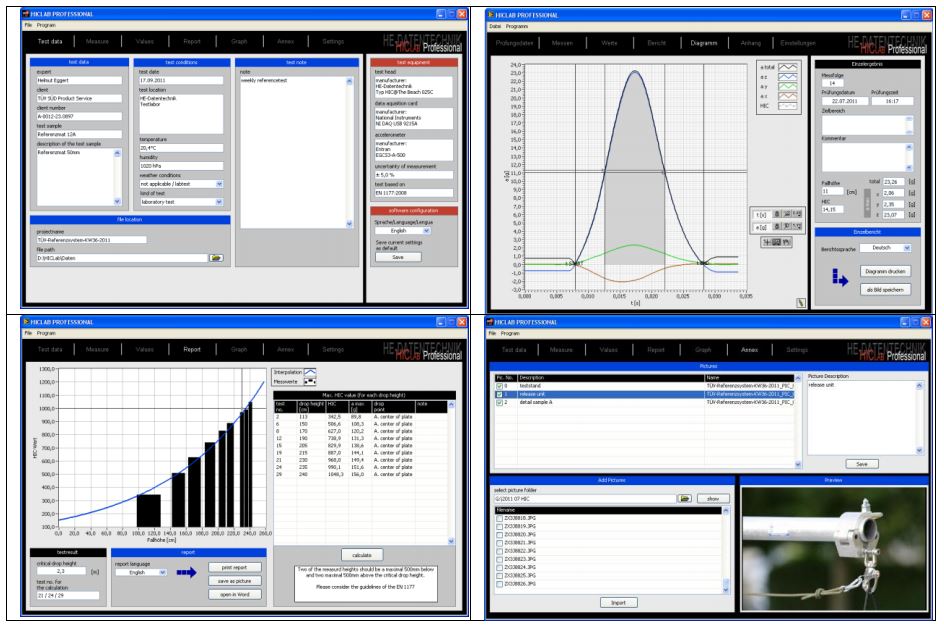

The previous version of the family of standards for playgrounds EN-1176 was agreed by CEN in 2008. The one that specified the test methods for verifying critical fall heights (CFH) was specifically the EN 1177: 2008. This norm considered the laboratory drop test on a sample as a means of product certification and as representative evidence of the absorption capacity of a continuous flooring alternatively to an “in situ” test.

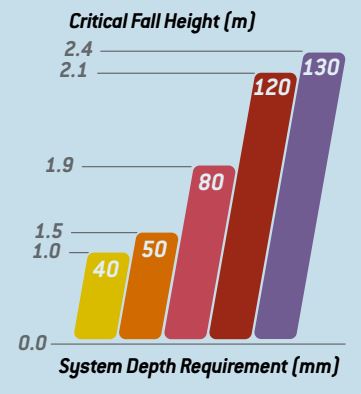

Consequently, flooring material suppliers or installers perform drop tests on samples with different thickness of flooring in the laboratory using their materials, proportions and following their own installation process during sample preparation, as a way of product certification.

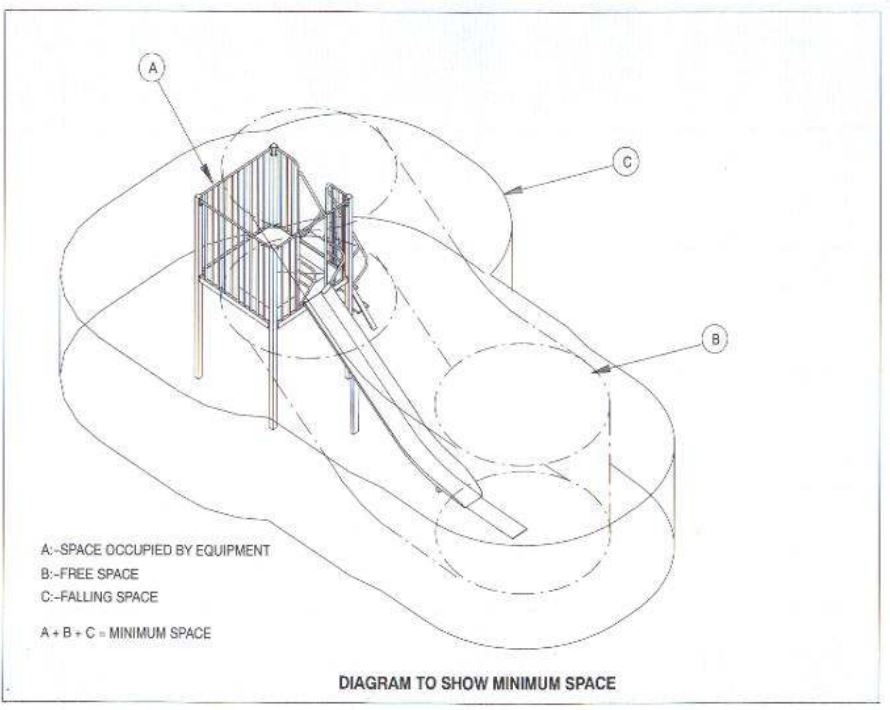

During the final inspection of a playground, in many countries, the inspector could check the thickness of the flooring using a simple measuring punch and certify as correct a playground when the thickness of the flooring and its certificate of critical fall height were enough to the maximum free fall height in of the different play equipment in each point of test.

In certain countries, however, inspectors made sure to do drop tests in the various areas of the playground and did not rely solely on the thicknesses of a sample-based product certificate to issue the certification of the playing area and I am glad they do this. The laboratory result on a sample is not a sufficient guarantee of the result achieved using the same thickness in a real installation, for many reasons such as the following:

- The type of base layer material used has the greatest influence on the drop height. The granule of the upper layer has little influence, but any change in the supplier of the base layer material can change the result. The granule size distribution, its bulk density, its average size or its shape (granule or buffing) greatly influence the result obtained for the same cushion layer thickness.

- The procedure used for the installation of the base layer, the degree of compression carried out on it, the use or not of rollers and their weight and the proportion of binder, can modify the value obtained for the same thickness.

- The temperature of the flooring in an outdoor environment during installation, the possible presence of heavy rain during installation, the compaction of the materials throughout the useful life of the area, the degree of use, the quality of its periodic cleaning maintenance, etc., can significantly reduce the absorption capacity that can be obtained in a sample or in a previous test on the same exact point.

- Although to a lesser extent, the type of binder may also have some influence.

In view of all these factors and the data on critical accidents in playgrounds, a long period of discussion was opened in the national standardisation committees as the one in Spain I was part of, with the aim of improving the safety of flooring and updating the standards for playgrounds to include new and innovative play equipment that had appeared on the market.

The CEN / TC 136 Committee, also author of the previous versions of 1998 and 2008, reviewed the entire family of EN-1176 standards and the EN-1177 standard itself, which was approved by the CEN member countries in 2018, renaming the current revision in force as EN-1177: 2018 + AC: 2019.

This new version introduces several changes, including an additional method of drop test “in-situ” for the moment of installation and in subsequent periods, which allow to confirm the suitability of the surfacing at the time of the test.

In connection with this standard, EN-1176-1: 2018 in its annex 8 introduces a procedure for the confirmation of the adequate level of shock absorption after installation before opening to the public or first use and draws attention to the fact that the critical drop height test results may vary over time or as a function of climatic conditions, advising regular testing in subsequent inspections.

In both standards there are sections that warn about the influence of regular cleaning maintenance on the shock absorption.

In conclusion, as manufacturers of materials for wetpour safety flooring we at CONICA are committed to providing, as indicated in these standards, a laboratory test report for the product with various thicknesses and critical heights achieved for our samples on a concrete sub-base, which serves as a useful reference, but the installer or the manager or owner of the area, at the end of the installation of the flooring, before it is opened to the public and also in regular periodic inspections, must carry out the drop tests at the relevant points of the area to ensure that the safety requirements of CFH of the surface are achieved and maintained during the useful life of the area.

The safety of our small playground users depends on it.

Take care