The top layer of the safety flooring for playgrounds is currently made of different materials, mainly EPDM, TPV, coated SBR and more recently Cork. The granule size distribution is key to achieve a nice visual finish.

These materials are also used in the latest generations of artificial grass pitches as infill padding that provides the necessary elasticity factor for the sport for which they are intended.

For safety flooring in playgrounds or recreational areas, one of the very important requirements is a nice visual finish of the flooring. This is an irrelevant issue in sport infill applications.

The granulation, in the case of elastomers, is produced after extrusion and vulcanisation of the material plates and is carried out by rotating knife machines that produce different sizes of granules and generate a certain amount of fine dust in the cutting process.

This dust and rubber powder must be removed from the final product but can be reused by adding it to base components for new productions of the material.

The presence of this dust during mixing with the polyurethane binder causes adhesion problems and requires additional binder consumption, while worsening the visual appearance of the flooring. The formulation of the material is also important to obtain a good bonding of the granules with the polyurethane binder. Not all combinations of binder and granules are a good fit.

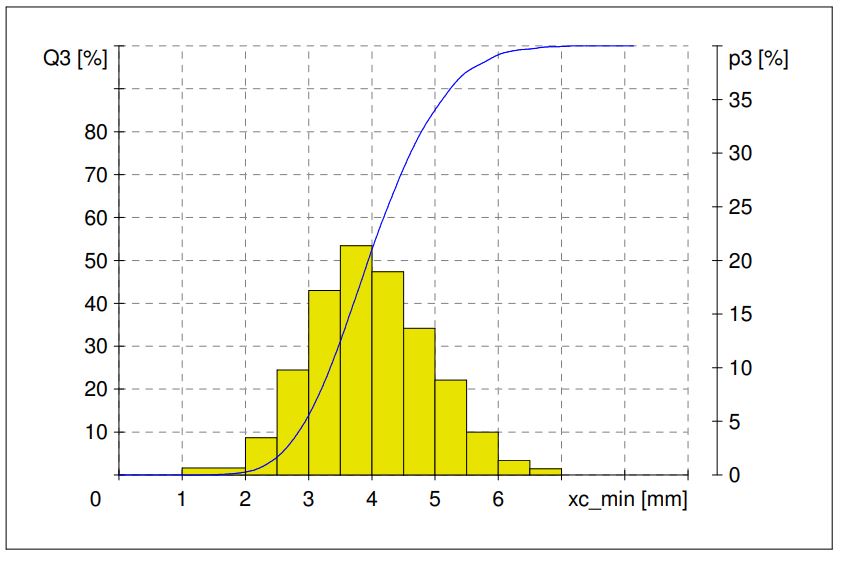

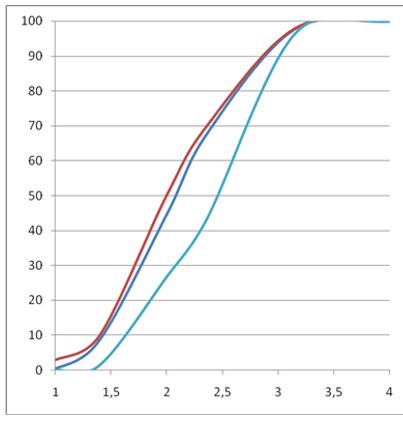

But what I want to highlight in this article today is the importance of granule size distribution in achieving a good visual finish of the flooring. You can see below different ways to graphically represent this granule size distribution from the Sieve Analysis.

In order to see a homogeneous, nice looking surface with well-closed pores, it is necessary to have granules of different sizes, in a continuous distribution such that they fit easily when applied and pressed with the trowel.

If the material has a discontinuous distribution with a high percentage of large and very small granules with little continuity in the size distribution, it will be more difficult to achieve a good visual appearance on the surface, independently of the installer skills.

As installers, the only influence you can have on this property is to select the right type of granulated product.

You must source a product that has an adequate granule size distribution. The manufacturer must maintain a consistent process and quality monitoring system and keep significant investment in maintenance of granulation machinery and dust removal or suppression systems to be capable of producing systematically and repetitively the same properties of the product.

I have good and bad news.

The bad news is they are usually not the cheapest.

The good news is you can find in CONICA some of the best ones.